Description

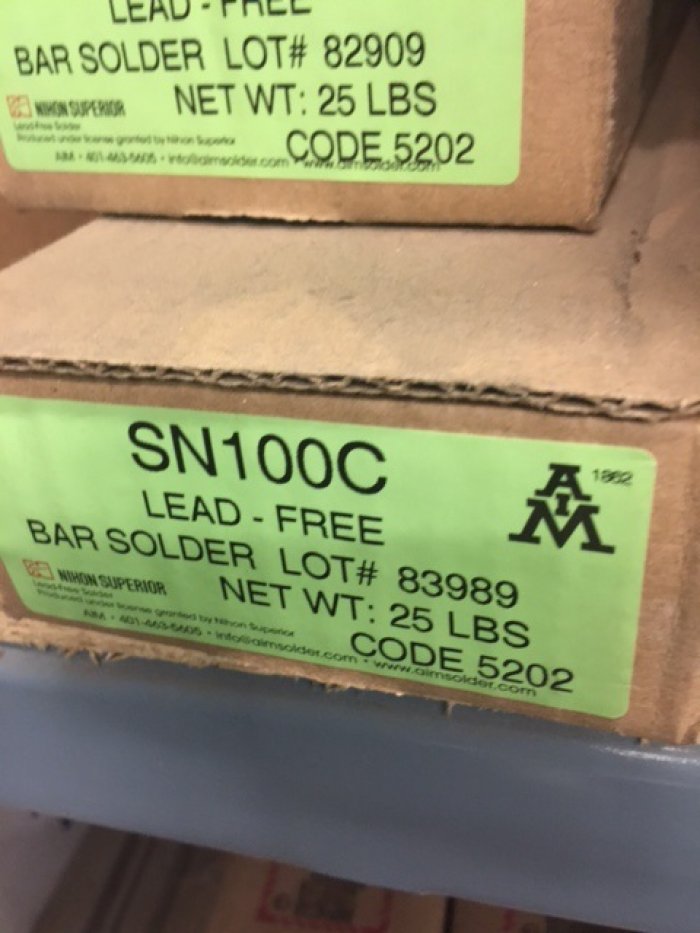

Description: SN100C? (Sn 0.05Ni + Ge) is a lead-free solder alloy developed by Nihon Superior in Japan. SN100C? offers user-friendly properties and has been proven in commercial production since 1999. The addition of nickel improves the wetting and flow properties of the cost effective tin-copper eutectic. This makes it possible to achieve excellent results in wave soldering at process temperatures comparable to the tin-lead solder it replaces. Performance in wave soldering at least matches that of more expensive silver-containing alloys and the resulting joints are smoother and brighter. SN100C? is available in bar, solid and cored wire, and solder paste. Solder Surface Comparison:

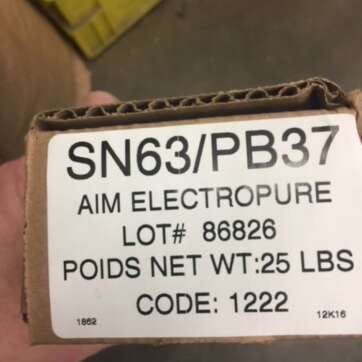

Wave Soldering: The main differences between wave soldering with Sn63/Pb37 tin-lead solder and wave soldering with SN100C? are: – The “process window”; the difference between the process temperature and the melting point of the solder is smaller. – At the recommended process temperatures the wetting SN100C? is slower. – Operators need to ensure that the wave soldering machine is designed to keep board and solder temperatures within these ranges throughout the process. Use the recommended starting settings as listed below. Preheat 110?-115?C (230?-239?F) Solder Wave 260?-270?C (500?-518?F) Dwell Time 5 seconds minimum

Safety: – Use with adequate ventilation and proper personal protective equipment. – Refer to the accompanying MSDS for any specific emergency information. – Do not dispose of any hazardous materials in non-approved containers.

Material Property Melting Temperature [?C] S.G. Specific Heat [J/KgK] Thermal conductivity [J/msK] Vickers Hardness Slow cooling Fast cooling Tensile strength [MPa] Elongation Electrical resistance [?m] Coefficient of Thermal Expansion 130-180?C 240?C Spread Factor 260?C 280?C Copper erosion rate at 260?C Thermal shock Electromigration Whiskers SN100C

Test method Ramp rate for different thermal analysis 20?/min S.G. measuring apparatus 25? Estimated value Estimated value Cast onto aluminum plate Cast onto insulating brick 10mm/min. (25?) For Terminal method (25?) Conditions: Load:10.0grams, sample ; Almina (20mm), Programmed temperature:10 /min.

Americas +1-401-463-5605 Europe +44-1737-222-258 Asia-Pacific +86-755-2993-6487?info@aimsolder.com?www.aimsolder.com?AIM IS ISO9001:2000 CERTIFIED